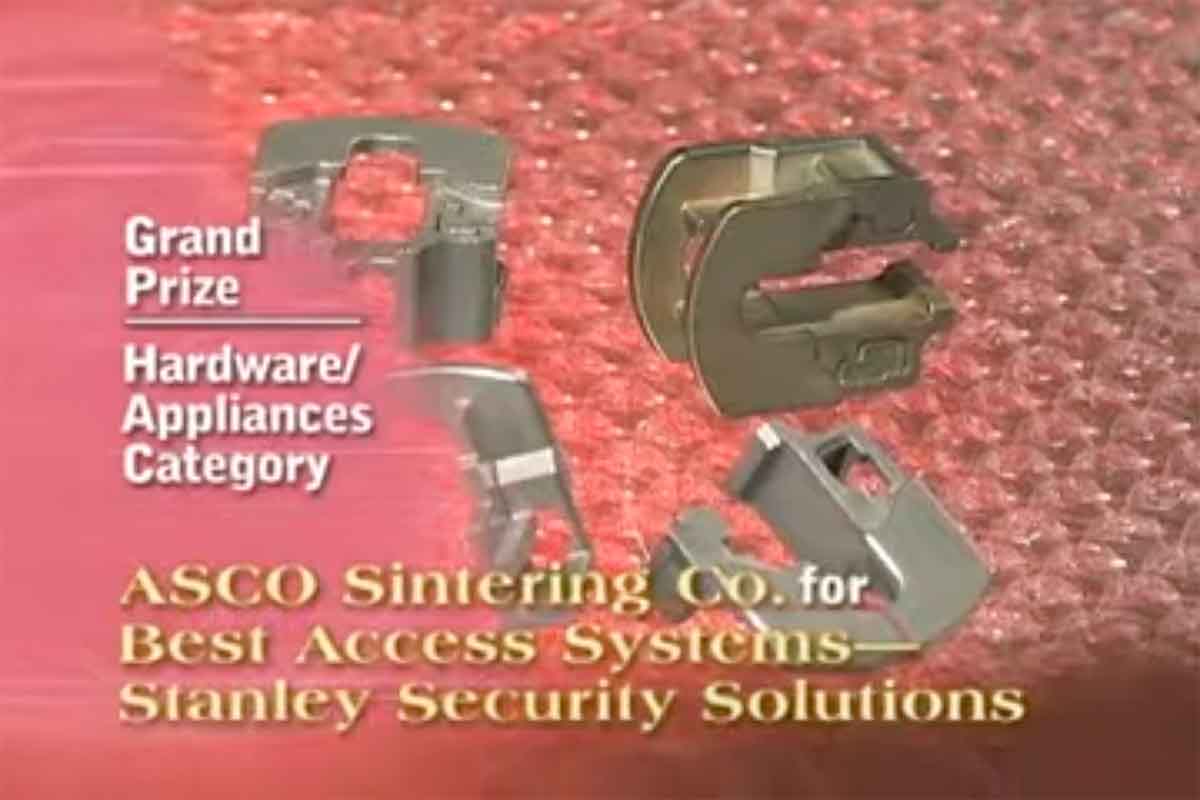

- 2017 Award of Distinction

- Lock Hardware Appliance

- Cost-saving 9-level Net-Shape geometry

- Copper Infiltrated Nickel Plated Steel

An Award of Distinction in the Hardware/Appliance Category of the 2017 Powder Metallurgy Design Excellence Awards Competition was presented to ASCO Sintering Co. for a Copper Infiltrated Steel Latch bolt used in a commercial door lock system.

This highly sophisticated and complex tool design, with its 9 levels of dimensional change, embodies the net shaped benefit provided by the Conventional Press and Sinter process by enabling 50% cost savings in both raw material and manufacture when compared to MIM or traditional manufacturing processes.

Statistical Process Controls are applied throughout the Compacting and Sintering processes to provide the extensive powder transfer and fill compensations necessary for even density distribution within all cross sections of the part before Electro Nickel plating per ASTM B633 Standards.

ASCO has supplied both Residential and Commercial Latch Bolts to the Door Lock Hardware Industry for over 50 years with each design solutions receiving qualification through the BHMA Cycle Testing standards for functional strength, security, finish and corrosion requirements.

Latch Bolts are manufactured complete from 70/30 or 80/20 brass, 300 or 400 Stainless Steel, or Copper-infiltrated steel.